- Whatsapp: +86-13567760620

- Email: [email protected]

Our new generation multi-functional plastic thermoforming machine represents over a decade of continuous improvement and innovation. It features advanced PLC control, utilizes Taiwan Yadke cylinder stretch forming, and offers optional servo stretch motors for enhanced performance. With an expanded molding layout and a modular temperature regulator module design, this plastic thermoforming machine delivers superior versatility and efficiency. Capable of producing a wide range of products including plastic cups, plates, dishes, packaging boxes, and various food and industrial packaging solutions, this machine ensures high-quality output tailored to diverse needs.

Technical Parameters

| Model | ZH-750/450 | ZH-650/350 |

| Materail | PP.PS.PET.PE.ABS | PP.PS.PET.PE.ABS |

| Sheet Width | 550-750mm | 500-650mm |

| Sheet Thickness | 0.3-2.5mm | 0.3-2mm |

| Max. Forming Area | 730x450mm | 650x350mm |

| Max. Product Deep | 170mm | 130mm |

| Forming Pressure | 0.5-0.8Mpa | 0.5-0.8Mpa |

| Forming Speed | 10-35cycles/min | 10-30cycles/min |

| Main Motor Power | 11kw | 11kw |

| Heating Power | 120kw | 80kw |

| Weight | 5ton | 4ton |

| Water Consumption | 40-45L/min | 40-45L/min |

| Air Consumption | 2500-3500L/min | 2500-3500L/min |

| Dimension | 4000x1700x2200mm | 3500x1600x2200 |

Equipment configuration

| Pillar Servo Construction Our pillar offers superior product quality across various shapes, including round, rectangular, oval, and square, even for larger sizes. This mechanism significantly increases the rate of finished products and ensures more stable operation, making it an excellent choice for high-efficiency production.

|

| PLC Our cup forming machine, features a Trio Schneider according to standard design, ensuring the stability, high efficiency, and low failure rate of the entire machine. This advanced system guarantees consistent and reliable operation, making it an ideal choice for high-precision production needs. |

| Human Machine Interface Our cup forming machine, is equipped with a ESTUN HMI, known for its advanced industrial grade and high durability. This state-of-the-art HMI enhances user interaction, ensuring efficient and reliable operation for all production needs.. |

| Oven Our system boasts seven times the maximum forming area, utilizing advanced little infrared ceramic tile heating for more uniform results. Constructed with 304 stainless steel for durability, it features Dongtai Tianbao heaters controlled by an intelligent temperature controller for precise temperature management. The oven structure adopts a pneumatic drawer design for easy access, while safety measures include manual blowing cooling to prevent sheet fall, ensuring safe and efficient operation. |

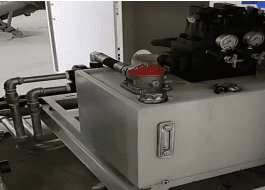

| Hydraulic Pump Hydraulic pump that supports the hydraulic system, allowing the bottom mold to move up within the station. This advanced hydraulic mechanism ensures precise and efficient forming, enhancing the performance and reliability of the cup forming machine. |

| MCB Our cup forming machine, features CHINT MCBs (Miniature Circuit Breakers) for reliable electrical protection and safety. CHINT MCBs are known for their durability and high performance, ensuring stable operation and protecting the machine’s electrical systems from faults and overloads. |

Output Products

Privacy Policy | SiteMap

Copyright © Zhejiang Wylong Machinery Co., Ltd.